insulating glass production line

WS 800

The small WS 900 insulating glass production line is suitable for the production of model panes with a straight supporting edge – a benefit that pays off.

It comprises the following components:

- In-feed with manual washing station for washing off most noticeable dirt, e.g. after sand blasting the glass panels

- Washing and drying unit with brushes and dryer fan

- Washing machine discharge point used as air cushion buffer station

- Indirectly illuminated control station with automatically relocatable crossbar and manual frame fitting

- Interim buffer upstream of the gas filling unit used to reduce cycle times

- Gas filling unit with distance measurement system

- Discharges into rack

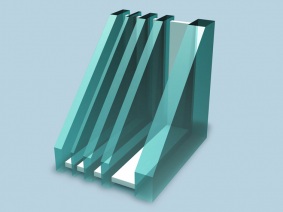

Five-layer insulation glass

Maximum thickness of 120 mm for the compressed unit and a maximum glass thickness of 20 mm for the individual panes to be washed

The WS 800 is suitable for the production of multi-layered insulation glass with and without gas filling in sizes ranging from

180 x 100 mm

to 800 x 2100 mm.

Or Optional max dimensions on customer request

Operating with new 12 inch HMI

Gas under control

- Washing and drying (not including compression)

- Two-layer to five-layer glass, with and without gas filling

- Gas filling only possible in selected interim chambers of the insulation glass unit

- Model pane pressing (with straight supporting edge) to final dimensions with a tolerance of +/- 0.25 mm

Productive benefits that impress

Due to rising energy prices, a good heat protection for the buildings is becoming increasingly important in order to save heating costs.

For example, in Germany there already is a heat protection ordinance that divides the houses into different energy classifying, up to passive house without heating.

Depending on the energy classification are then washed 3 times, 4 times or 5 times used insulating glass units.

With an average machine running time of 20 years ago to seeing all requirements should be covered.

Be already equipped for the challenges ahead and

Invest with which you have combined the classic and future requirements in a machine in a future-proof machine.

- Ideal addition to large insulation glass lines for the production of small panes with a small workforce

- Low investment costs while also reducing running cost and improving throughput

- Can be operated as needed by one to three operators